Members of DVIRC’s Advisory Council and Executive Network Group had the unique opportunity to tour Southco’s Concordville Plant and global headquarters.

Former Global Director of Engineering & Technology and member of DVIRC’s Advisory Council Al Frattarola arranged the tour with his former employer.

“During my 40-year tenure at Southco, I was responsible for overseeing the global engineering and technology integration and was responsible for multiple Southco facilities. As a member of the Advisory Council, I want to help share best practices across the region related to advanced technologies, workforce development, and continuous improvement.”

Attendees were welcomed by Steve Potter, Managing Director, Americas. Southco is a global leader of Engineered Access Hardware with global sales, distribution, and manufacturing locations with over 3500 employees.

Joe Acri, Operations Manager lead the group through the 120,000 square foot facility. Mike Lewis, Production Manager also supported the tour and answered attendee questions.

Acri began the tour sharing how Southco had embarked on their Lean Continuous Improvement journey 21 years ago. Members of the first Lean Champions class trained by DVIRC were prominently displayed in the lobby in which both Frattarola and Acri were part of the first graduating classes.

The CI culture is still going strong and is a part of the fabric of the organization. All employees are provided with training and are empowered to suggest improvements anywhere they believe could be improved. Southco’s leadership encourages and supports the Lean culture, which has paid off in return on investment and retaining talent.

The emphasis on CI, technology adoption, and empowering and supporting their employees was demonstrated throughout the tour.

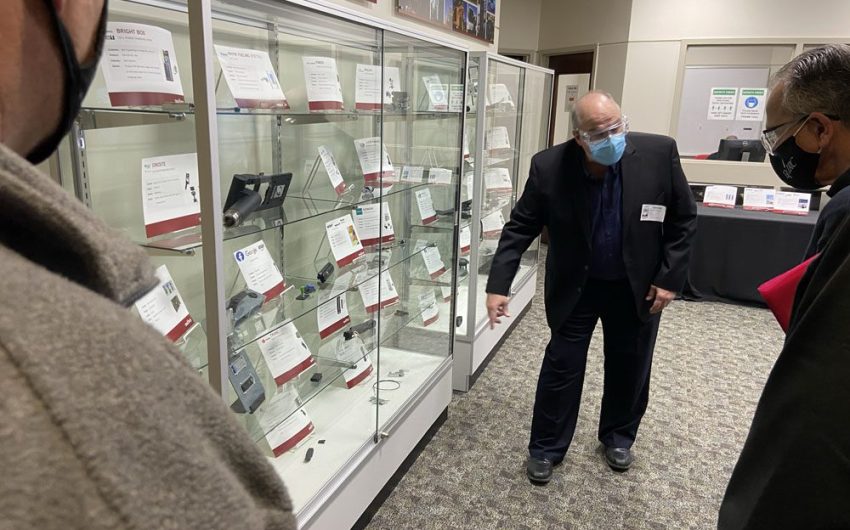

Acri started the tour showcasing a variety of access solution products, and describing the company. “For over 70 years, Southco has been a leading global designer and manufacturer of engineered and innovative access solutions for a wide variety of transportation and industrial applications, medical equipment, data centers and more.”

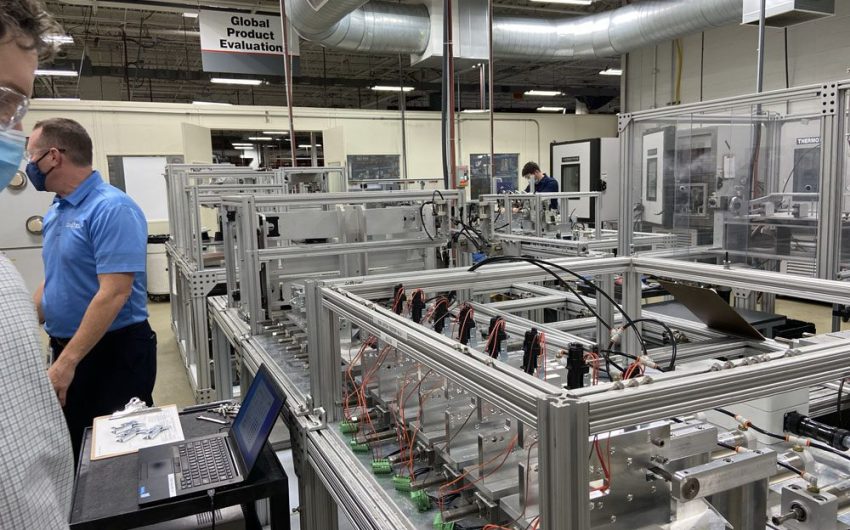

The group toured the diverse product lines and learned about the ongoing workforce and technology performance improvements happening real time. Southco focuses on continuous improvement as part of their culture and a competitive advantage.

Each of the five value streams were presented by some of their team leaders, each empowered to ensure the highest standards and quality work product.

James Lantz – Rivet manufacturing

Product Evaluation & Testing – Bryan Graham

Randy Navickas – Engineering and injection molding operations

Scott McCarthy – Automated Assembly operations

Jason Woodruff – Shipping and receiving – vertical carousels