Ameriscend

Ameriscend Turns to DVIRC for Strategic Planning, Continuous Improvement Training and Coaching

The Fredericks Company

DVIRC Helps The Fredericks Company Establish E-Commerce Presence and Acquire a Significant Increase in Revenue and New Customers

LavAzza

Global Coffee Roaster LavAzza Retains DVIRC to Support Continuous Improvement Culture

Liberty Coca-Cola

Beverage Icon Liberty Coca-Cola Retains DVIRC Six Sigma Experts Resulting in $1.4MM in Initial Cost Savings

Johnson Matthey

DVIRC Winning Teams™ Generates 600% Return on Investment through Lean Process Improvements Combined with Employee Training for Johnson Matthey

PAC Strapping Products

PAC Strapping Increases Sales and Improves Efficiency Through DVIRC’s Six Sigma Training

Container Research Corporation

CRC increases production by 300% with DVIRC Lean training

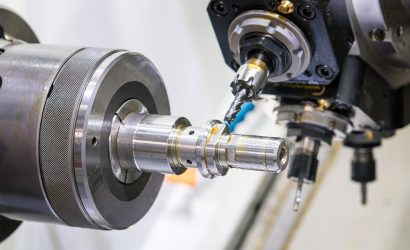

Germantown Tool and Manufacturing

DVIRC Helps Germantown Tool Generate $6 Million in New Revenue Through Market Expansion

Metal Edge International

DVIRC Executive Coaching Helps Metal Edge Improve Operations Performance and Staff Development

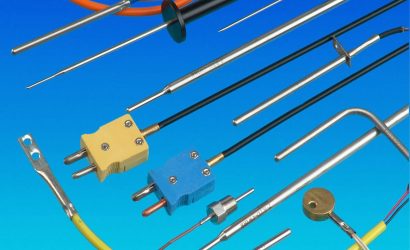

Probes Unlimited

Probes Unlimited increases efficiency and capacity with DVIRC’s Training and Continuous Improvement Support

Ehmke Manufacturing

Ehmke Manufacturing Goes Lean, Improves Productivity & Sales

PAC Strapping Products

PAC Strapping Enters New Era With Upgraded Software

Haskell Education

Furniture Manufacturer Experiences Best Growth Ever with DVIRC’s Marketing and Sales Support

Polysciences, Inc.

Organizational Development Training Yields Significant Results to Chemical Manufacturer

PDC Machines

PDC Machines saves $500,000 in costs, brings in $7 million in new business through work with DVIRC

Corry Rubber Corporation

DVIRC Lead Generation Yields Significant, Long-Term Sales Growth

The Fredericks Company

Internet and Website Project with DVIRC Yields Substantial Improvements

Manufacturing Extension Partnership Member

Medical Device Manufacturer Accelerates Time to Market with Supplier Scouting

Tiger Optics

ERP Upgrade Improves Visibility, Efficiency and Productivity

Virginia Manufacturing Extension Partnership

DVIRC Delivers Quick-Turn Supplier Scouting

U.S. Armed Services Supplier

DVIRC Provides Supplier Scouting for Novel DoD Medical Product

U.S. Armed Services Affiliate

DVIRC Aids DoD in Researching Medical Training Database System

U.S. Armed Services Affiliate

DVIRC Research Team Develops Technology Landscape for DoD Material Management

U.S. Armed Services Affiliate

DVIRC Spearheads Department of Defense Research into 21st Century Maintenance Processes

Rebling Plastics

Plastics Company CEO Finds Business Advice, Leadership Support, and Training from DVIRC Network Groups

Sentinel Process Systems

Strategy, Marketing, and Networking Services help Sentinel Process Systems Double Sales, Expand Company, and Save Costs

Advent Design Corporation

Strategic Planning Results in 500% Sales Increase and Dramatic Business Growth

Barry Callebaut

Manufacturing Executive Group Pays Big Dividends

EFE Labs

Sales and Marketing Partnership with DVIRC Results in Profitable Growth

Universal Service Associates

Generate a Steadier Stream of Work

Stockwell Elastomerics

Identifying Market Behavior and Potential Opportunities

HPT Pharma

Building a Growth Strategy

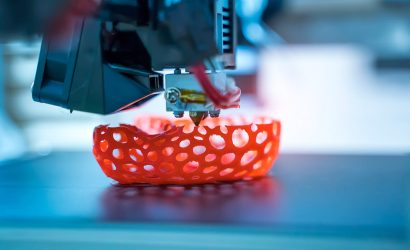

ProtoCAM

Highly Advanced Technology Research Solutions

The EF Precision Group

Develope a Strategic Marketing Roadmap

LEM Products, Inc.

Prioritize Resources and Actions to Drive Topline Growth

Stockwell Elastomerics

Enhance Customer Service and Revenue Stream

Puritan Products

Identify Industries, Screen for Synergy and Generate Leads

Westinghouse Lighting

Clarifying Core Competencies and Competitive Advantages

Galaxy Wire & Cable

Setting Priorities and Action Plans

NCC Automated Systems

Developing a Strategic Plan to Ensure Future Success

Dontech, Inc

Gain Focus and Set Meaningful Priorities

Edmund Optics, Inc

Improve ERP System and the Visibility of Manufacturing Capabilities

Dooley Gasket and Seal, Inc.

Formalize Processes, Analyze Software Needs and Find the Right Vendor

Turkey Hill

Empowering Employees to Identify and Solve Problems

Tech Tag & Label

Reducing Operational Costs to Maintain Competitiveness

Merit Medical

DVIRC helps Merit Medical reduce costs, cycle times, and grow sales

Blommer Chocolate

Creating Value Through Leadership, Strategy, Culture and Operations

Probes Unlimited

Reducing Cost to Stay Competitive

SEPTA

Improving Performance, Freeing Up Resources and Improving Customer Satisfaction

Met-Pro Corporation (Now CECO Environmental Corp.)

Transforming Manufacturing and Production Processes

Engineered Arresting Systems Corporation (ESCO) (Now Safran)

Creating a culture that drives improvement

Superior Tube

Heading down the Lean path for five consecutive years of profitability

Packaging Progressions, Inc. (pacproinc®)

Strategic Plan Fuels Company Growth

Lasko Corporation

Winning Teams™ Program Yields Dramatic Improvements in People & Process

Community Professional Loudspeakers

Level One Lean Certification: A Catalyst for Improvement

C&L Rivet

Expanding The Executive Team & Realizing A Strategic Growth Plan

Johnson Matthey

The Power of Empowerment

Metal Edge International

From Working In The Business to Working On The Business

DSM Biomedical

Working Smarter With Lean Six Sigma

[ close ]