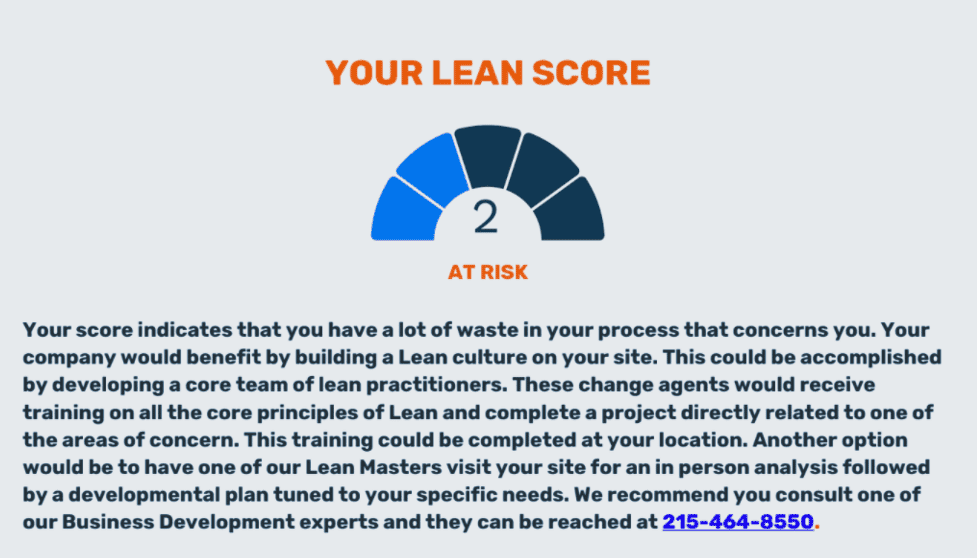

To be successful, Lean Manufacturing requires buy-in and commitment from the entire company – from the C-suite through the shop floor. DVIRC’s approach to Lean Consulting includes coaching employees, teaching them how to implement processes, and helping them develop skills that will ensure your company’s long-term stability, overall growth, and competitiveness.

Our experts work with you to assess your operations and identify the desired organizational direction. They evaluate all of the Continuous Improvement services available, as well as the desired behaviors (sometimes referred to as soft skills) for sustainability.